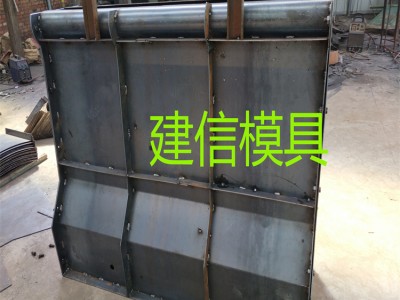

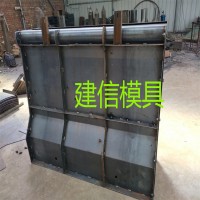

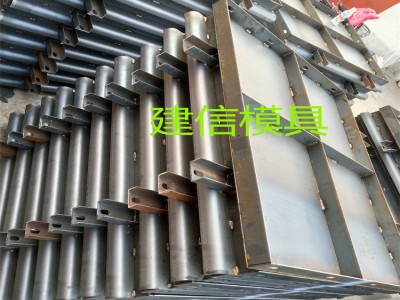

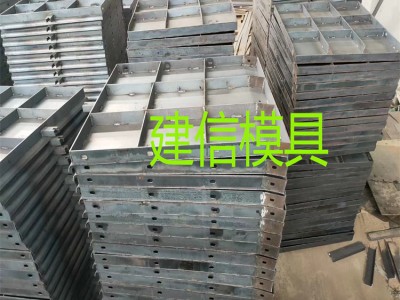

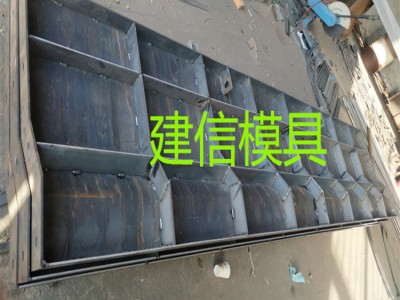

防撞墙钢模具在脱模时需要注意的问题也很多,这个模具的构成只有两块钢板,但是在实际生产制作时,我们需要固定钢板,所以在防撞墙钢模具脱模时,首先

应该拆除的是这些固定设施,固定设施主要是拉杆,脱模后得到了防撞墙产品,但刚脱模时,混凝土产品处于初凝状态,需要进行一段时间的养护,养护时间必

须在7天以上。否则,混凝土产品容易出现裂缝,养护时一般进行浇水养护,无论什么季节,无论什么天气,养护期间,必须保证防撞墙钢模具产品的湿度,在

炎热的天气下,为了保证湿度,增加浇水的次数,保证产品的质量,在实际使用时更加耐用。

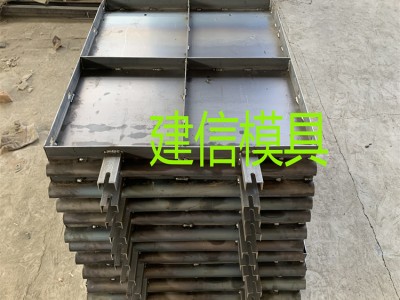

There are also many problems that need to be paid attention to when demoulding the steel mold of the anti-collision wall. The

composition of this mold is only two steel plates, but in the actual production, we need to fix the steel plate, so when demoulding

the steel mold of the anti-collision wall, we should first

These fixed facilities should be removed. The fixed facilities are mainly

pull rods. After demoulding, the anti-collision wall products are obtained. However, when demoulding, the concrete products are in

the initial setting state and need to be cured for a period of time. The curing time must be

It must be more than 7 days. Otherwise,

concrete products are prone to cracks, and watering maintenance is generally carried out during maintenance. No matter what season or weather, the humidity of anti-collision wall steel mold products must be ensured during maintenance

In hot weather, in order to ensure the humidity, increase the watering times and ensure the product quality, which is more durable in actual use.